Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The content of calcium powder has a direct impact on the quality of PVC drainage pipes. To understand the impact of calcium powder on PVC drainage pipes, let's first understand the production formula of PVC drainage pipes:

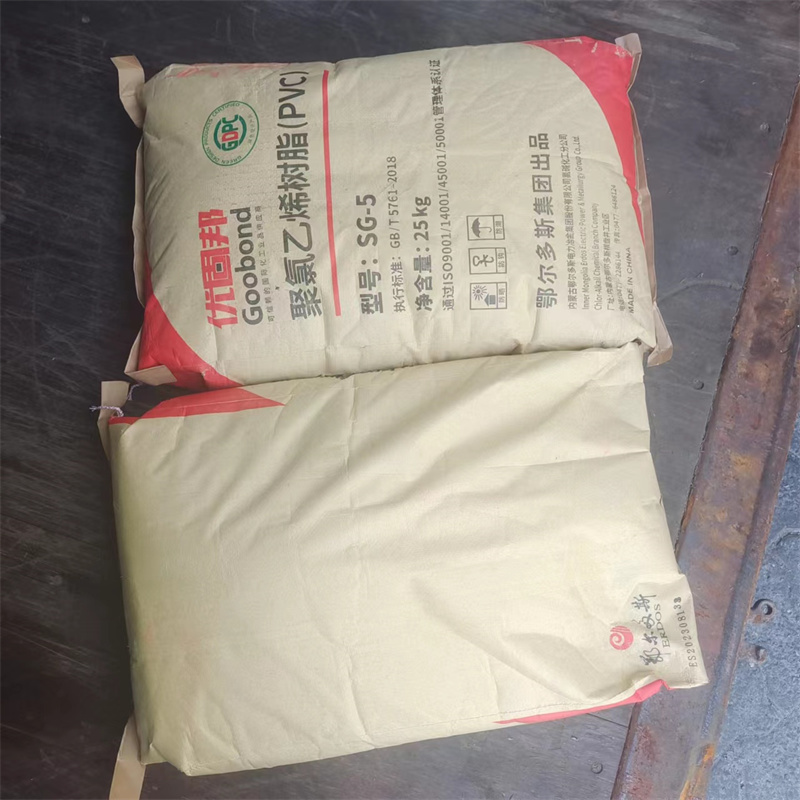

(1) Pvc Resin:

PVC Resin is the main component of PVC drainage pipes, accounting for 60% to 80% of the total amount. It can improve the rigidity, heat resistance, and chemical corrosion resistance of pipes.

(2) Fillers and enhancers:

Commonly used fillers and reinforcing agents include calcium powder (calcium carbonate), graphite, glass fiber, etc. They can improve the strength, hardness, wear resistance, and impact resistance of pipelines.

(3) Heat stabilizers and lubricants:

During the processing of PVC, an increase in temperature can cause the decomposition of PVC molecules, thereby affecting the quality of the pipeline. Adding heat stabilizers can prevent the decomposition of PVC, while lubricants can improve the flowability of PVC, making pipeline molding easier.

(4) Colorants and other additives:

Colorants are used to add color to PVC pipes to meet different needs. Other auxiliary agents include antioxidants, anti ultraviolet agents, etc., which can enhance the service life of pipelines.

By decomposing the components of PVC drainage pipes, it can be seen that the calcium powder (calcium carbonate) we refer to is an important filler in the production of PVC pipes. So, why do we add calcium powder to PVC pipes? It can be simply summarized as the following three factors:

(1) Enhance pipeline rigidity and strength

Due to the high density of calcium powder, it can enhance the overall density of the pipeline, significantly increasing the rigidity and strength of PVC drainage pipes, which makes the pipeline more able to withstand external stress and pressure.

(2) Enhanced stability

Calcium powder helps to improve the dimensional stability of PVC pipes, enabling them to maintain stable size and shape in response to temperature and humidity changes.

(3) Reduce costs

Due to the fact that calcium powder is a relatively inexpensive filling material, its addition can increase product volume while reducing manufacturing costs.

Although adding calcium powder can bring some benefits, excessive addition of calcium powder can have a counterproductive effect, causing the pipeline to become brittle, reducing its toughness and impact resistance. For example, mechanical properties such as drop hammer impact, flattening, water pressure will decrease, and physical performance indicators such as density, longitudinal shrinkage, and gelation will be poor. In order to obtain high-quality PVC pipes, it is necessary to make a reasonable choice and balance between the amount of calcium powder added and the density of the pipes.

In practical applications, it is often heard that 50 parts of calcium or 100 parts of calcium refer to the content of calcium powder. For example, adding 50 kilograms of calcium powder to 100 kilograms of PVC resin is 50 parts of calcium, and adding 200 kilograms of calcium powder is 200 parts of calcium. Similarly, the higher the content of calcium powder, the worse the quality of the pipe. Normally, PVC water supply pipes typically have 10-20 parts of calcium, PVC wire pipes typically have 40-50 parts of calcium, and PVC drainage pipes can even reach 100 parts of calcium or higher.

Therefore, in actual production, it is necessary to consider the strength, pressure resistance, and corrosion resistance of the pipeline based on its usage requirements, and select an appropriate amount of calcium powder to achieve the required pipeline quality.

June 25, 2023

April 03, 2023

November 15, 2024

November 13, 2024

In the world of materials, there is a seemingly ordinary but super-widely used substance-polyvinyl alcohol. Polyvinyl alcohol (PVA) is a water-soluble polymer. It has many unique properties, which...

Since November, the DOP market has shown a firm trend, with the market center of gravity slightly rising, but the overall amplitude is limited. Take the East China market as an example, the price of...

1. Can ordinary PVC be made into PVC paste resin? Answer: ordinary PVC cannot be made into PVC paste resin. 2. What calcium powder is added to PVC paste resin? Answer: calcium carbonate powder is...

With the development of modern ceramic technology, people have put forward higher requirements for the performance of ceramics. Sodium tripolyphosphate is an additive commonly used in architectural...

Email to this supplier

June 25, 2023

April 03, 2023

November 15, 2024

November 13, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.