In the world of materials, there is a seemingly ordinary but super-widely used substance-

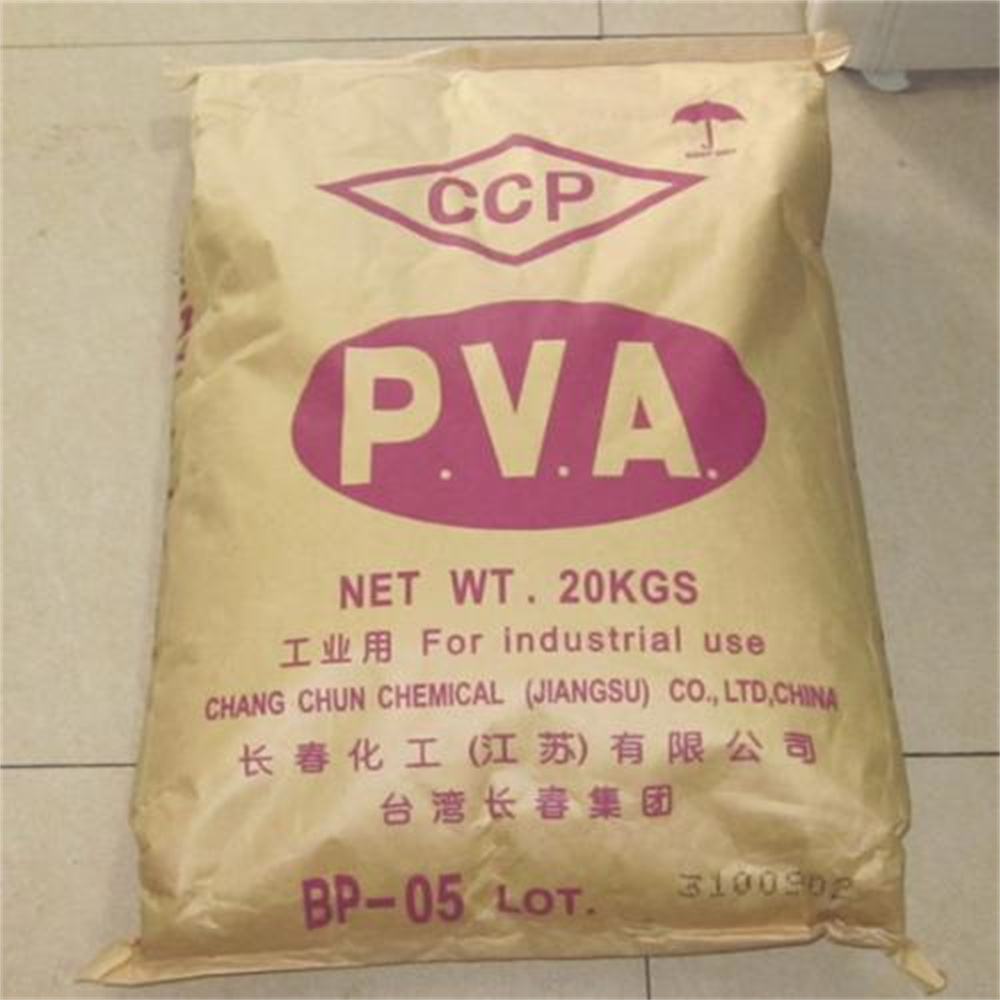

Polyvinyl Alcohol. Polyvinyl alcohol (PVA) is a water-soluble polymer. It has many unique properties, which make it play an important role in many fields. Polyvinyl alcohol (PVA) is a new functional environmental protection material. As an innovative green technology, it has gradually entered people's field of vision in recent years. With its excellent environmental protection performance and diversified functions, it provides a brand-new solution for all walks of life. PVA (polyvinyl alcohol) is a kind of polymer compound, and it has become a leader in the field of new materials with its excellent properties. PVA has the characteristics of good biocompatibility, non-toxicity, environmental protection and biodegradability, and is an important representative of green environmental protection materials. In addition, PVA has excellent mechanical properties, electrical insulation and barrier properties, which makes it have a wide application prospect in many fields. PVA (polyvinyl alcohol), as an environmentally friendly material with good biodegradability and availability, is widely used in various fields. Its high strength, high transparency and high temperature resistance make it an ideal choice to replace traditional plastic materials. Not only that, PVA material also has good biocompatibility and biodegradability, which is in line with the current social pursuit of sustainable development. I. characteristics of polyvinyl alcohol PVA 1. Oil resistance and organic solvent resistance: Soluble in water, the aqueous solution is transparent. Its solubility is mainly determined by the degree of polymerization and alcoholysis. With the decrease of alcoholysis degree, the water solubility increases, and the dissolution temperature decreases accordingly. When alcoholysis degree is 88%, the water solubility is the best. PVA can be dissolved in polar solutions containing hydroxyl groups (glycerol, ethylene glycol,

Acetic Acid, acetaldehyde, etc.), but it is easy to gel, and insoluble in general nonpolar organic solvents and inorganic acids (H2SO4, HCl, etc.). Film-forming property: PVA aqueous solution is easy to form a film, and the formed film is colorless and transparent, with good mechanical strength and smooth surface without stickiness. The membrane is permeable to water vapor, but the permeability of hydrogen, oxygen, carbon dioxide and other gases is very low, and the change of external temperature has little influence on the membrane. Adhesion: PVA aqueous solution can adhere to porous substances such as fiber, wood and paper with good adhesion. Miscibility: PVA can be miscible with starch, gum, synthetic

Resin, cellulose derivatives and various surfactants and has good stability. Chemical resistance: At room temperature, the pH value of PVA aqueous solution is generally about 5-7, and its viscosity is stable, hardly influenced by weak acids, weak bases or organic solvents (esters, ketones, higher alcohols and hydrocarbons), and its oil resistance is extremely high, but it can be depolymerized and decomposed by peroxides such as H2O2. Heat resistance (thermal stability): PVA softens when heated to 130 ~ 140℃, and its properties hardly change, only its color turns yellow. Long-term heating at 160℃ darkens the color. When the temperature is 200℃, the water solubility decreases due to intermolecular dehydration. When the temperature is above 200℃, intramolecular dehydration occurs. When it is close to 300℃, it is completely decomposed into water, acetic

ACID, acetaldehyde and crotonaldehyde (there is no adverse effect during sizing and drying). Color rendering: PVA can form molecular adducts with dyes Congo red, iodine, copper hydroxide, boric acid and salt, which can be used to identify desizing and detergency and distinguish PVA with different alcoholysis degrees. The difference of PVA properties is mainly determined by its polymerization degree and alcoholysis degree. For Chuanwei brand PVA with different alcoholysis degrees, with the decrease of alcoholysis degree, the viscosity decreases slightly, the film strength decreases, the elongation increases, and the adhesion to hydrophobic fibers increases. Storage stability of PVA aqueous solution: Compared with other water-soluble polymers (such as CMC), PVA is a polymer with low viscosity, and its dilute aqueous solution is very stable at room temperature. PVA aqueous solution will not denature during storage; Although the alcoholysis PVA concentrated solution is transformed into gel at low temperature, it is easy to become solution once heated. Non-toxic: pure PVA is non-toxic, can be used as an adhesive for cosmetics and food packaging, and is completely harmless in contact with skin. Second, the environmental advantages of PVA new materials 1. Biodegradable: PVA new material has good biodegradability, which can be quickly decomposed into water and carbon dioxide in the natural environment, effectively reducing environmental pollution. 2. Low toxicity and harmlessness: The content of toxic substances in the production process of PVA new materials is strictly controlled to ensure human health and environmental safety. 3. Save resources: PVA new materials have excellent recyclability, which can effectively reduce resource waste and realize green and sustainable development. Third, the application fields of PVA new materials 1. In the field of medicine, polyvinyl alcohol can be used in the production of drug sustained-release agents and medical dressings. It can control the release rate of drugs and improve the curative effect of drugs. At the same time, the medical dressing made of polyvinyl alcohol has good water absorption and air permeability, which can promote wound healing. 2. Packaging industry: PVA material has high barrier performance, which can effectively block oxygen, water vapor, etc., and prolong the shelf life of food. In addition, PVA can also be made into biodegradable plastic packaging materials. 3. In textile industry: PVA fiber has good hygroscopicity, breathability and softness, and can be widely used in textiles, non-woven fabrics and other fields. Polyvinyl alcohol can be used for warp sizing. It can enhance the strength and wear resistance of yarn, and improve the textile efficiency and product quality. At the same time, the fibers made of polyvinyl alcohol have good hygroscopicity and comfort, and are widely used in underwear, sportswear and other fields. 4. In the field of construction, polyvinyl alcohol can be used to modify cement and mortar. It can improve the cohesiveness, crack resistance and water resistance of cement and mortar, and prolong the service life of buildings. At the same time, polyvinyl alcohol can also be used in the production of waterproof coatings and adhesives, providing reliable guarantee for construction projects. 5. In the food field: PVA is also indispensable. As a food packaging film and food additive, it guards people's food safety with its good biocompatibility and biodegradability. 6. In papermaking industry, polyvinyl alcohol can be used as paper surface sizing agent and reinforcing agent. It can improve the strength, smoothness and water resistance of paper, and make paper more high-quality and durable. In addition, polyvinyl alcohol can also be used in the production of special paper, such as filter paper and battery separator paper. 7. In the agricultural field, polyvinyl alcohol can be used as coating materials for pesticides and fertilizers. It can control the release speed of pesticides and fertilizers, improve their utilization rate and reduce environmental pollution. At the same time, polyvinyl alcohol can also be used in the production of soil improvers, improving soil structure and improving soil fertility. In daily life, PVA functional environmental protection materials can be used to make various products, such as food packaging bags, shopping bags, disposable tableware and so on, which not only facilitates people's lives, but also protects the environment. Compared with traditional plastic materials, PVA materials will not pollute the environment, effectively reduce the burden on the earth caused by human beings and contribute to sustainable development. Let's explore the future together, embrace green life and make PVA functional environmental protection materials an indispensable part of our environmental protection journey. Iv. Market Situation of PVA Coated High Barrier Film As a hydrophilic polymer, polyvinyl alcohol (PVA) has a unique molecular structure-carbon chain as the main chain and a large number of hydroxyl groups in the side chain, which endows it with excellent film-forming, non-toxic, odorless, high transparency, excellent gas barrier and mechanical properties. Especially in the context of the growing global demand for green materials, PVA is an ideal choice for packaging, separation and purification, biomedicine and other fields because of its completely biodegradable characteristics. In terms of technological innovation, the research and development of PVA coated high barrier film represents a major breakthrough in the industry. By coating PVA with nano-inorganic substances on the surface of polyethylene film, the problem of poor barrier performance of traditional three-layer polyethylene co-extrusion packaging film was successfully solved through fine printing and compounding process, and the comprehensive performance of the product was improved without significantly increasing the cost. This innovative technology not only meets the market demand for high-performance packaging materials, but also opens up a new road for the development of PVA industry. In terms of market application, with the rapid growth of China's economy and the upgrading of consumer demand, the plastic packaging industry has increasingly strict requirements for materials. PVA coated high barrier film occupies an important position in the market because of its excellent performance and environmental protection characteristics. Especially in the field of food and drug packaging, PVA coated high barrier film effectively prolongs the shelf life of products and ensures the health and safety of consumers by virtue of its high barrier performance. In addition, with the improvement of environmental awareness, more and more enterprises began to pay attention to the environmental performance of packaging materials, so PVA coated high barrier film was widely concerned and favored. In terms of industrial chain, a number of competitive PVA coated high barrier film manufacturers have emerged in China. For example, a novel modified polyvinyl alcohol (PVA) aqueous coating liquid with high barrier performance can be applied to the aseptic black-and-white packaging film (commonly known as Bailibao) of fresh milk packaging. This new coating liquid not only improves the barrier performance of the product, but also reduces the production cost, which has won the market competitive advantage for the enterprise. Looking into the future, PVA industry will continue to maintain the momentum of rapid development. With the improvement of environmental awareness and policy support, PVA coated high barrier film and other environmental protection packaging materials will usher in a broader market space. At the same time, with the continuous progress of science and technology and the improvement of consumers' requirements for product performance, PVA industry will also face more opportunities and challenges. Therefore, PVA industry needs to continuously strengthen technological innovation and industrial upgrading, improve product quality and performance, so as to meet market demand and promote the sustainable development of the industry.