Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

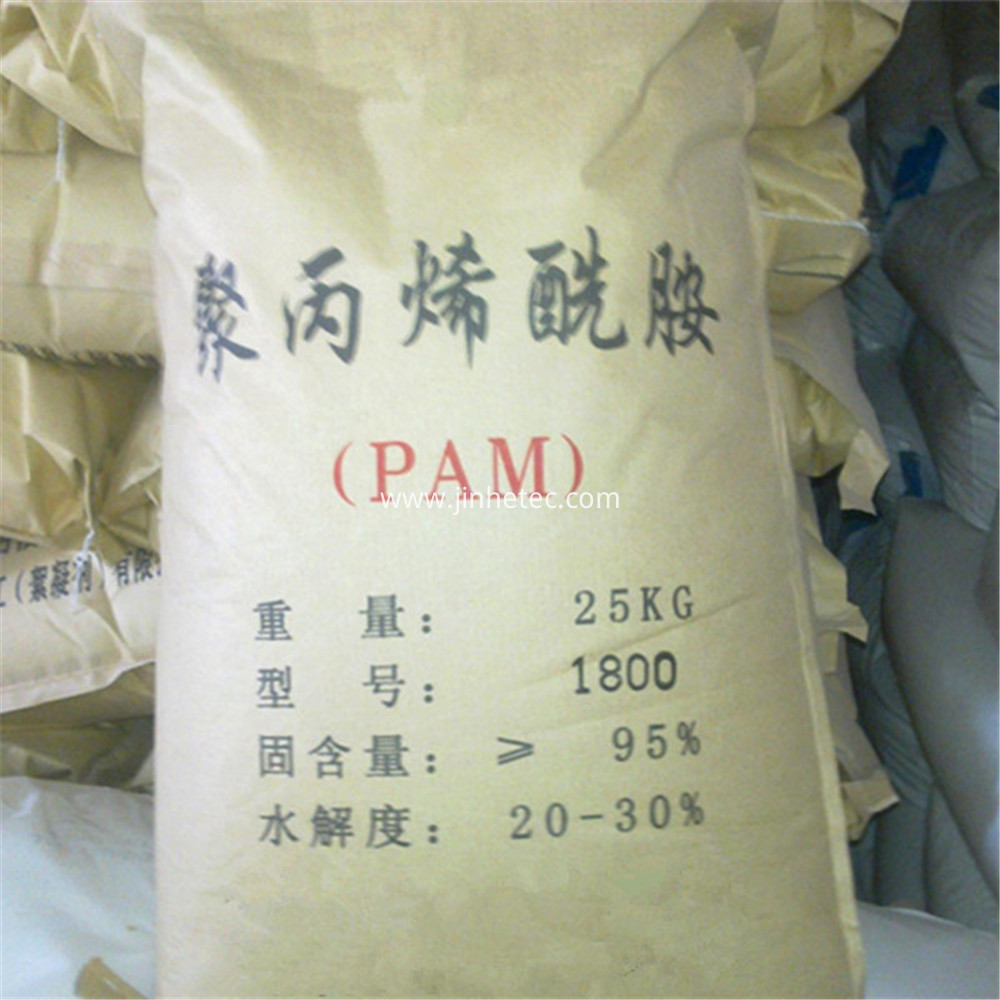

1、 What are the technical indicators of Polyacrylamide?

The technical indexes of polyacrylamide are generally molecular weight, hydrolysis degree, ionic degree, viscosity, residual monomer content, etc., so the quality of PAM can be judged from these indexes!

1. Molecular weight

The molecular weight of PAM is very high, and it has been improved in recent years. The molecular weight of PAM used in 1970s is generally millions; after 1980s, most of the high-efficiency PAM molecular weight is more than 15million, some of which reach 20million. Each PAM molecule is formed by polymerization of more than 100000 acrylamide or sodium acrylate (the molecular weight of acrylamide is 71, and the molecular weight of PAM containing 100000 monomers is 7.1 million). Generally, PAM with high molecular weight has better flocculation performance, with the molecular weight of acrylamide 71 and PAM containing 100000 monomers of 7.1 million. The molecular weight of polyacrylamide and its derivatives can be divided into low molecular weight (less than one million), medium molecular weight (1 million to 10 million), high molecular weight (10-15 million), and supermolecular weight (over 15million).

Molecular weight of polymer organic matter is not completely uniform even in the same product, and the nominal molecular weight is its average.

2. Degree of hydrolysis and ionic degree

The ion degree of PAM has a great influence on its use effect, but its suitable value depends on the type and nature of the materials being processed, and different optimal values will be available under different circumstances. If the ion strength of the treated material is high (with more inorganic substances), the ion degree of PAM used should be higher, otherwise it should be lower. Generally, the anionic degree is called hydrolysis degree. The ionic degree is generally referred to as cation.

Ion degree =n/ (m+n) *100%

PAM produced in early stage was formed by polymerization of a monomer of polyacrylamide, which did not contain COONa group. NaOH heating shall be added before use to hydrolyze part of CONH2 to -coona. The reaction formula is as follows:

-CONH2 + NaOH -→ -COONa + NH3↑

Ammonia is released during hydrolysis. The hydrolysis ratio of amide group in PAM is called the hydrolysis degree of PAM, which is called anion degree. The use of this PAM is inconvenient and its performance is poor (heating hydrolysis will make the molecular weight and performance of PAM decrease obviously), and it has been rarely used since 1980s.

Modern PAM has many kinds of products with different anion degrees. Users can choose appropriate varieties according to the needs and through actual tests. They can be used after dissolution without further hydrolysis. However, for customary reasons, some people still call the dissolution process of flocculant hydrolysis. It should be noted that the meaning of hydrolysis is water decomposition, chemical reaction, and the hydrolysis of PAM has ammonia gas release; while dissolution is only physical action, and there is no chemical reaction. The two are different in nature and should not be confused.

3. Residual monomer content

The content of PAM is the content of acrylamide in the process of polymerization of acrylamide into polyacrylamide, which is not completely reactive and remains in the product of polyacrylamide, and is an important parameter to measure whether it is suitable for food industry. Polyacrylamide is non-toxic, but acrylamide has a certain toxicity. In the industrial product polyacrylamide, it is inevitable that there are trace amount of polymerized acrylamide monomer. Therefore, the residual monomer content in PAM products must be strictly controlled. The content of residual monomer in PAM used in drinking water and food industry is not more than 0.05% in international regulations. The value of famous foreign products is less than 0.03%.

4. Viscosity

PAM solution is very viscous. The higher the molecular weight of PAM, the higher the viscosity of PAM solution. This is because PAM macromolecules are long and thin chains, and have a great resistance to movement in the solution. The essence of viscosity is to reflect the friction force in solution, also known as the internal friction coefficient. The viscosity of the solutions of various polymer organic compounds is higher and increases with the increase of molecular weight. One method to determine molecular weight of polymer organic matter is to measure the viscosity of a certain concentration solution under certain conditions, and then calculate its molecular weight according to a certain formula, which is called "viscosity average molecular weight".

2、 How to choose the type of PAM correctly?

Polyacrylamide can be divided into four types, namely nonionic, anion, cation and amphoteric polyacrylamide according to their ionic characteristics. According to molecular weight, there are many models derived from different specifications of molecular weight and ionic degree. Facing the disordered specification system in the market, it is very difficult to select the best polyacrylamide model for their own sewage system. How to solve the common problems of selecting polyacryl in sewage or sludge is very difficult.

1. Understand the source of sludge

Sludge is an inevitable product in Sewage Treatment. First, we should know the source, nature, composition and solid content of sludge. According to the main components of sludge, sludge can be divided into organic sludge and inorganic sludge.

Generally speaking, cationic polyacrylamide is used for treating organic sludge, while anionic polyacrylamide is used for inorganic sludge. When the alkalinity is strong, it is not easy to use cationic polyacrylamide, while when the ACID is strong, it is not suitable to use anionic polyacrylamide. When the solid content of sludge is high, the amount of polyacrylamide is larger.

2. The choice of the ionic degree of polyacrylamide

For the sludge to be dehydrated, different flocculants of different ionic degrees can be selected through small experiments, and the best suitable polyacrylamide can be selected, which can achieve the best flocculant effect, and make the dosage minimum and save cost. The key to ion selection is as follows:

(1) Size of floc

Size of floc: too small floc will affect the drainage speed, too much floc will bind more water and reduce the biscuit size. The size of flocs can be adjusted by selecting the molecular weight of polyacrylamide.

(2) Floc strength (moisture content)

Strength of floc: floc should be stable and not broken under shear action. The increase of molecular weight of polyacrylamide or the selection of appropriate molecular structure can improve the stability of floc.

(3) Mixing of polyacrylamide and sludge:

Polyacrylamide must react with sludge sufficiently at a certain position of dehydration equipment and flocculation will occur. Therefore, the viscosity of polyacrylamide solution must be suitable. It is the key factor to be successful to mix the two with sludge under the existing equipment conditions. The viscosity of polyacrylamide solution is related to its molecular weight and concentration.

(4) Dissolution of polyacrylamide:

Only when the solution is good can flocculation be fully exerted. The previous discussion on the dissolution process of polyacrylamide is actually the ripening process of polyacrylamide. Sometimes, the dissolution speed needs to be accelerated. At this time, the concentration of polyacrylamide solution can be increased.

So the best product choice should be decided by the laboratory beaker experiment.

3. Molecular weight selection of polyacrylamide

Molecular weight of polyacrylamide refers to the length of the molecular chain in the molecule. The molecular weight of polyacrylamide is between 5-18 million. Generally speaking, the higher the molecular weight of polyacrylamide products, the greater the viscosity. However, in use, the higher the molecular weight of products, the better the use effect. In specific use, according to the actual application industry, water quality and treatment Equipment and other conditions to determine the appropriate molecular weight of polyacrylamide.

Polyacrylamide is a polymer coagulant aid. According to its average molecular weight, the products can be divided into three categories: low molecular weight (< 1 million), medium molecular weight (2-4 million) and high molecular weight (> 7 million).

Polyacrylamide is a kind of water-soluble organic polymer with molecular weight ranging from several million to tens of millions. The domestic high molecular polyacrylamide are: nonionic polyacrylamide (abbreviated NPAM, molecular weight 8-15 million), anionic polyacrylamide (abbreviated APAM, molecular weight 8-20 million), cationic polyacrylamide (abbreviated CPAM, molecular weight 8-12 million, ionic degree 10% - 80%).

If only used as coagulant aid, the higher the molecular weight is, the more compact the floc is, and the less medication is needed. However, the molecular weight of anionic polyacrylamide should not exceed 20 million.

If in sludge dewatering. When using belt filter press, the molecular weight should not be too high. If the molecular weight is too high, the filter cloth may be blocked and the dehydration effect may be affected. For another example, if you use centrifugal filter press, the molecular weight requirement is higher, because the centrifugal filter press requires that the flocs can be shear resistant as much as possible, so you should choose products with relatively high molecular weight.

It can be seen from the above that the choice of molecular weight and ionic degree is not absolute. Before choosing polyacrylamide, it is better to do type selection test and operation test on computer, so as to get the most accurate data and the optimized polyacrylamide has higher cost performance.

June 25, 2023

April 03, 2023

November 15, 2024

November 13, 2024

In the world of materials, there is a seemingly ordinary but super-widely used substance-polyvinyl alcohol. Polyvinyl alcohol (PVA) is a water-soluble polymer. It has many unique properties, which...

Since November, the DOP market has shown a firm trend, with the market center of gravity slightly rising, but the overall amplitude is limited. Take the East China market as an example, the price of...

1. Can ordinary PVC be made into PVC paste resin? Answer: ordinary PVC cannot be made into PVC paste resin. 2. What calcium powder is added to PVC paste resin? Answer: calcium carbonate powder is...

With the development of modern ceramic technology, people have put forward higher requirements for the performance of ceramics. Sodium tripolyphosphate is an additive commonly used in architectural...

Email to this supplier

June 25, 2023

April 03, 2023

November 15, 2024

November 13, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.