Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

preface:

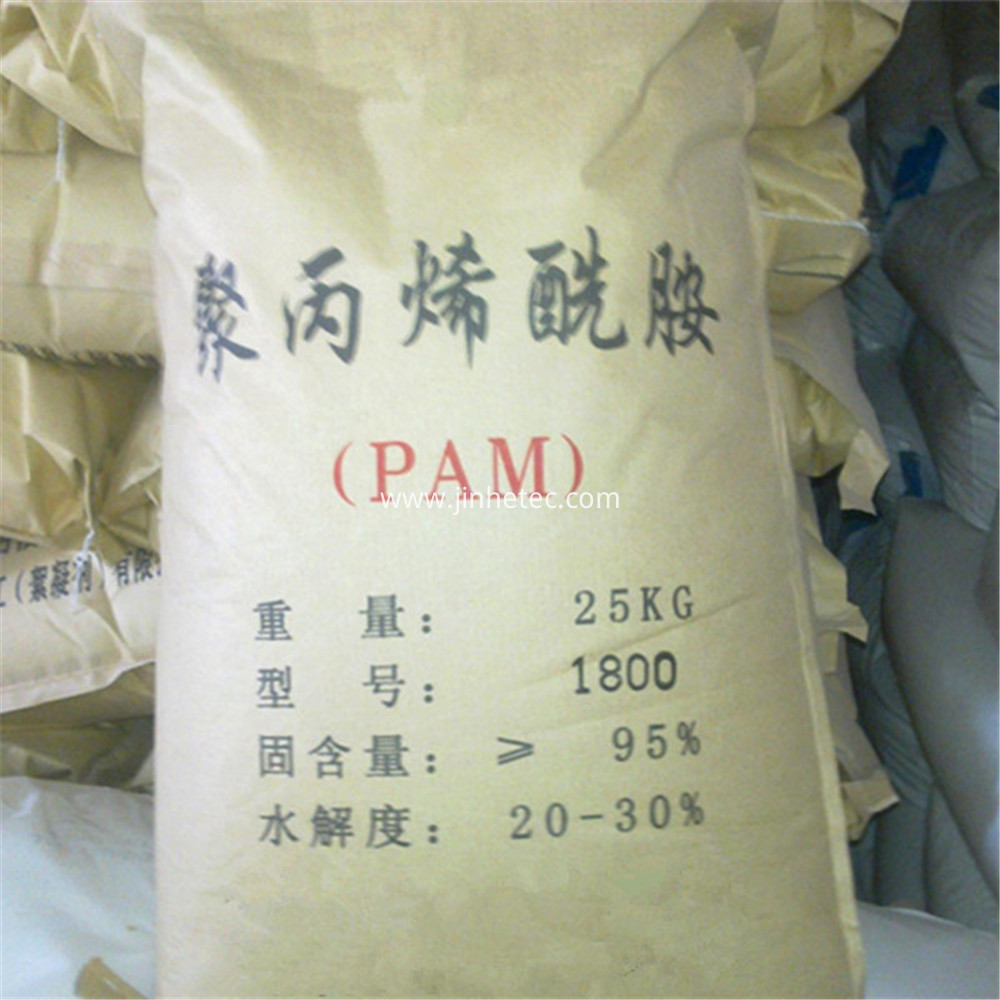

Flocculant PAM, also known as Polyacrylamide, is commonly used for sewage flocculation, sludge dewatering, turbidity removal, filter aid and other purposes. Common models are divided into cation, anion and non-ion.

It is believed that everyone has encountered the poor flocculation effect of adding polyacrylamide in Sewage Treatment. Today, we will simply talk about the factors that affect the flocculation effect of PAM.

1、 Selection of Polyacrylamide Model

Cationic polyacrylamide is suitable for the flocculation treatment of wastewater with high toxicity and organic substances and the dehydration process of organic sludge.

Anionic polyacrylamide is suitable for flocculation treatment of wastewater with large suspended particles, high turbidity and positive charges.

Non ionic polyacrylamide has strong flocculation function in acidic water because it does not have the activity of acylamine on the side chain of ionic functional group molecule.

2、 Molecular weight of flocculant

The larger the molecular weight of flocculant is, the better the flocculation effect is. However, the molecular weight is too large, it is difficult to dissolve, and the manufacturing cost is also high. You need to choose the most suitable one according to the sewage situation. The commonly used molecular weight is 3-18 million.

3、 Dosage of flocculant polyacrylamide

The dosage is generally different according to the water quality. The flocculation effect cannot be achieved when the dosage is small in sewage, and the liquid will become viscous when the dosage is large. Generally, it is recommended to conduct beaker flocculation test before use.

The best dosage of flocculant is that all flocculants are adsorbed on the surface of solid particles, and the settling speed of flocs reaches the maximum. The optimum dosage varies with the ionic property, molecular weight and pH value of the suspension of the flocculant, which can be determined by test methods.

4、 Proportion of PAM dissolved in polyacrylamide

The dissolution ratio of anionic PAM and non-ionic polyacrylamide is one thousandth, and the optimal dissolution ratio of cationic polyacrylamide is two thousandths.

5、 PH value of water

The pH value of water has a great influence on the use effect of inorganic flocculants, and the pH value is related to the type, dosage and coagulation sedimentation effect of flocculants selected. H+and OH - in water participate in the hydrolysis reaction of flocculant. Therefore, pH value strongly affects the hydrolysis rate of flocculant, the existing form and performance of hydrolysis products. Taking the aluminum salt that coagulates by generating Al (OH) 3 charged colloid as an example, when the pH value is less than 4, Al3+can not be largely hydrolyzed to Al (OH) 3, mainly in the form of Al3+ions, and the coagulation effect is extremely poor. When the pH value is between 6.5 and 7.5, Al3+is hydrolyzed and polymerized into Al (OH) 3 neutral colloid with high degree of polymerization, and the coagulation effect is good. When pH value is greater than 8, Al3+is hydrolyzed to AlO2 -, and the coagulation effect becomes very poor. The alkalinity of water has a buffer effect on the pH value. When the alkalinity is not enough, lime and other agents should be added to supplement. When the pH value of water is high, add ACID to adjust the pH value to neutral. In contrast, polymer flocculants are less affected by pH value.

6、 Temperature of water

Water temperature affects the hydrolysis rate of flocculant and the formation rate and structure of alum floc. The hydrolysis of coagulation is mostly endothermic reaction. When the water temperature is low, the hydrolysis speed is slow and incomplete. At low temperature, the viscosity of water is large, Brownian motion is weakened, the number of collisions between flocculant colloidal particles and impurities in water is reduced, and the shear force of water is increased, which hinders the mutual adhesion of coagulation flocs; Therefore, although the dosage of flocculant is increased, the formation of flocs is still slow, and the structure is loose, the particles are small and difficult to remove. Low temperature has little effect on polymer flocculant. However, it should be noted that when using organic polymer flocculants, the water temperature should not be too high, and the high temperature will easily cause the organic polymer flocculants to age or even decompose into insoluble substances, thus reducing the coagulation effect.

7、 Flocculant dosing sequence

When multiple flocculants are used, the best dosing sequence needs to be determined through tests. Generally speaking, when inorganic flocculant and organic flocculant are used together, inorganic flocculant shall be added first, and then organic flocculant shall be added. The particle size of treated impurities is 50 μ When m is above, the organic flocculant is usually added first to adsorb the bridge, and then the inorganic flocculant is added to compress the double electric layer to destabilize the colloid.

8、 Mixing speed

In the mixing stage, the flocculant and water are required to be mixed quickly and evenly. In the reaction stage, it is necessary to create sufficient collision opportunities and good adsorption conditions to allow the flocs to have sufficient growth opportunities, and prevent the generated small flocs from being broken. Therefore, the mixing strength should be gradually reduced and the reaction time should be long enough. The rotating speed of the mixer shall be generally controlled at 50-250 r/min.

June 25, 2023

April 03, 2023

Product Introduction: Polyacrylamide (PAM) is a linear polymer with the chemical formula (C3H5NO) n. At room temperature, it is a crystalline solid, and the products include glue, latex, white powder...

1、 What are the technical indicators of polyacrylamide? The technical indexes of polyacrylamide are generally molecular weight, hydrolysis degree, ionic degree, viscosity, residual monomer content,...

Email to this supplier

June 25, 2023

April 03, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.