Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: H110

Brand: Jinhe

Classification: Chemical Auxiliary Agent

Place Of Origin: China

Types Of: Adsorbent

Application Field: Coating Auxiliary Agents, Plastic Auxiliary Agents, Rubber Auxiliary Agents

Density G/cm3@25℃: 0.95

Product Name: Polyethylene wax (PE wax)

Other Name: polymer wax

Type: H110

Softening Point (℃): 112±3

Viscosity Cps@149℃: 10~20

Penetration (dmm@25℃): 2-4

Color: White

Physical Shape: Flakes/powder

Molecular Weight: 3500-4000

Packaging: 25kg bag

Productivity: 200000MT

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 5000ton/Month

Certificate: ISO9001:2000

HS Code: 3404900090

Port: Tianjin,Qingdao

Payment Type: L/C,T/T,Others

Incoterm: FOB,CFR

Good Performance PE WAX For Color Masterbatch

Polyethylene Wax has good light resistance and chemical properties, can be used as a carrier of pigments, can improve the abrasion resistance of paints and inks, improve the dispersibility of pigments and fillers, prevent pigments from sinking to the bottom, and can be used as a flattening agent for paints and inks.

Polyethylene wax (PE wax), also known as polymer wax, is referred to as polyethylene wax. It is widely used because of its excellent cold resistance, heat resistance, chemical resistance and abrasion resistance. In normal production, this part of the wax can be directly added to the polyolefin processing as an additive, which can increase the gloss and processing performance of the product. As a lubricant, it has stable chemical properties and good electrical properties. Polyethylene wax has good compatibility with polyethylene, polypropylene, polyvinyl acetate, ethylene-propylene rubber and butyl rubber. It can improve the fluidity of polyethylene, polypropylene and ABS and the release properties of polymethyl methacrylate and polycarbonate. Compared with PVC and other external lubricants, polyethylene wax has a stronger internal lubricating effect.

| Technical indicators | Testing method | H110 |

| Softening point (℃) | ASTM D3954 | 112±3 |

| Viscosity cps@149℃ | ASTM D3236 | 10~20 |

| Density g/cm3@25℃ | ASTM D1505 | 0.95 |

| Penetration (dmm@25℃) | ASTM D1321 | 2-4 |

| color | ASTM D1544 | White |

| physical shape | Flakes/powder | |

| molecular weight | 3500-4000 |

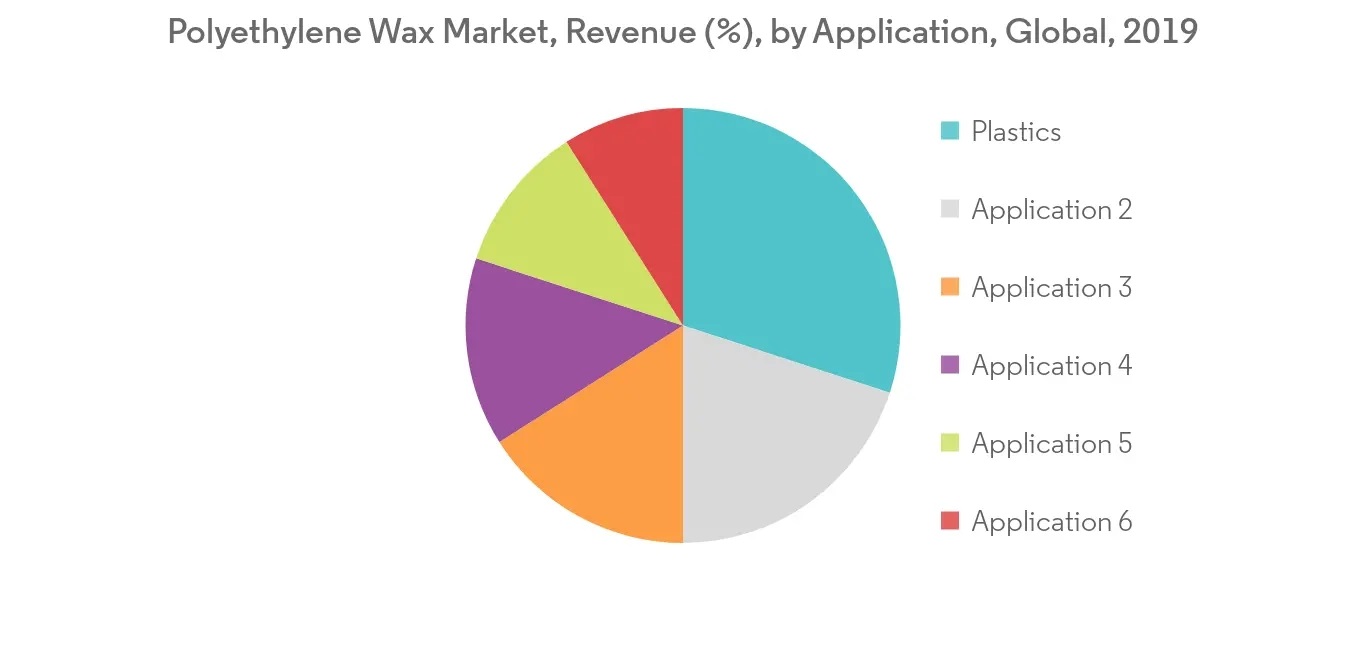

Application of polyethylene wax

1. Concentrated color masterbatch and filler masterbatch. It is used as a dispersant in the processing of color masterbatches, and is widely used in polyolefin color masterbatches. It has good compatibility with polyethylene, polyvinyl chloride, polypropylene and other resins, and has excellent external lubrication and internal lubrication.

2. PVC profiles, pipes and composite stabilizers are used as dispersants, lubricants and brighteners in the molding process of PVC profiles, pipes, pipe fittings and PE.PP to enhance the degree of plasticization and improve the toughness and surface smoothness of plastic products. .And widely used in the production of PVC composite stabilizer.

3. The ink has good light resistance and chemical properties, can be used as a carrier for pigments, can improve the abrasion resistance of paints and inks, improve the dispersibility of pigments and fillers, and has good anti-settling effect. It can be used as a flattening agent for paints and inks. The product has good luster and three-dimensional effect.

4 Wax products are widely used in the production of various wax products such as floor wax, car wax, glazing wax, candles, crayons, etc., to improve the softening point of wax products, increase their strength and surface gloss.

5. Cable material Used as a lubricant for cable insulation materials, it can enhance the diffusion of fillers, increase the extrusion rate, increase the mold flow, and facilitate demolding.

6. Hot-melt products are used for all kinds of hot-melt adhesives, thermosetting powder coatings, road marking paints, scribing paints, as dispersants, have good anti-settling effect, and make the products have good gloss and three-dimensional effect.

7 Rubber As a rubber processing aid, it can enhance the diffusion of fillers, increase the extrusion rate, increase the mold flow, facilitate demolding, and improve the surface brightness and smoothness of the product after demolding.

8 Cosmetics Make products have good luster and three-dimensional effect.

9 Injection molding Save machine power lubrication and enhance product surface gloss.

We could supply PVA Resin, PVC Resin, Titanium Dioxide, PVC Paste Resin, Iron Oxide, Chrome Green, Sodium Tripolyphosphate,

We could supply PVA Resin, PVC Resin, Titanium Dioxide, PVC Paste Resin, Iron Oxide, Chrome Green, Sodium Tripolyphosphate,

Sodium Hexametaphosphate, Carbon Black, Chlorinated Polyethylene, Modified Starch, Tung Oil, PVB Resin, PEG, Polyethylene Glycol, PE WAX etc.

Product Categories : PE WAX

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.