Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The operating load of PVC enterprises increased, the inventory was higher than that in the same period of previous years, the downstream orders were limited, the supply and demand pattern deteriorated, and the price continued to weaken, so as to accelerate the demand for destocking. However, there is uncertainty in calcium carbide supply in winter, which adds uncertainty to the trend of PVC. Therefore, we are cautious and bearish on PVC.

At present, the supply and demand pattern of PVC is weak. The operating load of enterprises is maintained at a relatively high level, the social inventory is high, and the market supply is sufficient. However, due to the seasonal influence, downstream enterprises are not active in procurement, so it is difficult to accelerate the process of PVC destocking, which has a strong suppression on PVC prices, which is also the leading logic at present. However, from the cost side, the policy and winter transportation problems add more uncertainty to the supply of calcium carbide in the later stage. It is not appropriate to be too pessimistic about the price of calcium carbide. The drag of the cost side on PVC is not only gradually relieved, but also does not rule out the occurrence of supporting PVC in the later stage. Based on the above factors, we are cautiously bearish on PVC prices.

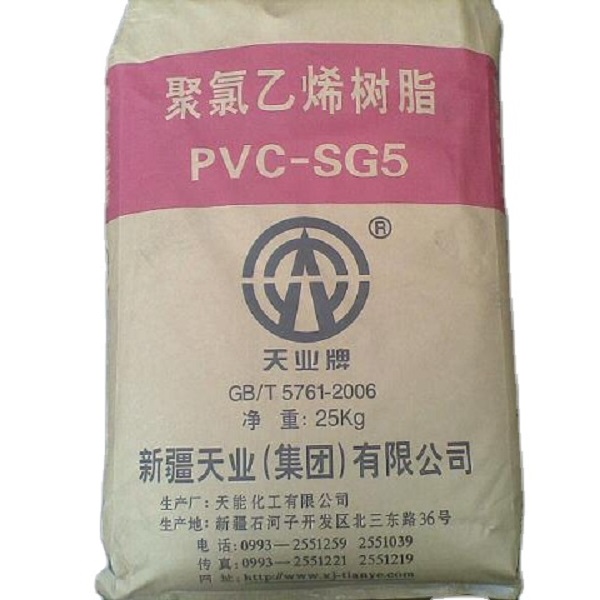

We offer Sinopec Pvc Resin S1000 , Sinopec PVC S1300 , Sinopec PVC S1050, tianye PVC Resin SG3, Tianye PVC RESIN SG5 , Tianye PVC RESIN SG8, ERDOS PVC Resin SG5, Zhongyan PVC RESIN SG5 , Beiyuan PVC RESIN SG5 , Beiyuan PVC SG3 , Beiyuan PVC SG8.

June 25, 2023

April 03, 2023

February 26, 2024

October 24, 2023

Since the beginning of this year, the price of polypropylene (PP) in Europe has shown a steady upward trend. Market insiders point out that part of the reason for this phenomenon is the increase in...

abstract PVC powder has shown strong performance in the past two trading days after a sharp decline in the early stage. Last Friday (October 20th), there was a slight increase in export volume and...

Different production processes are the key to determining the differentiated development of China's chemical industry and the main driving force for chemical upgrading. Production enterprises can...

【 Introduction 】 The spot export price of PVC resin in the United States fell by 15-20 US dollars per ton during the week. The market estimates that the PVC powder price in Asia in October may be...

Email to this supplier

June 25, 2023

April 03, 2023

February 26, 2024

October 24, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.